On June 15, 2025, at 13:20 local time, a brand-new SANY STS crane collapse at Singapore’s Tuas Port, during delivery and installation procedures. This SANY STS crane collapse Singapore port analysis reveals critical insights into modern port equipment failure scenarios.

The incident occurred at a non-operational berth within the Tuas Port expansion project. Remarkably, no injuries were reported, and port operations continued uninterrupted.

Incident Overview and Timeline

Initial Incident Report

The SANY STS crane collapse Singapore port analysis begins with the Maritime and Port Authority of Singapore (MPA) and PSA Singapore joint statement confirming the incident. The ship-to-shore crane accident investigation commenced immediately following the collapse.

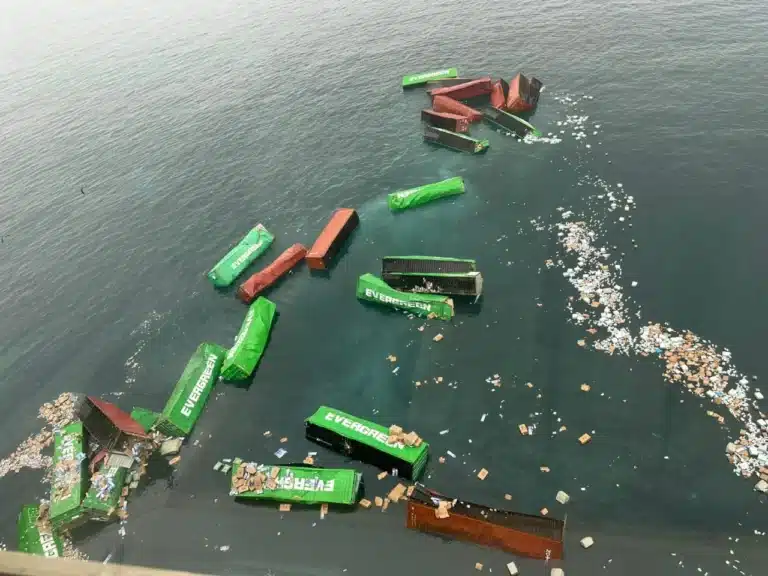

At approximately 13:20 PM Singapore time, the double-trolley STS crane tipped over during positioning operations. Emergency response teams secured the area within minutes of the port equipment failure analysis requirements.

Media Coverage Development

June 16, 2025, marked intensive media coverage of the crane installation safety procedures breach. Channel News Asia and The Straits Times published comprehensive reports detailing the maritime infrastructure incident.

Social media platforms circulated video footage showing the exact moment of collapse. The Online Citizen identified SANY Heavy Industry as the manufacturer, while Vertikal.net provided preliminary technical analysis.

Technical Specifications and Analysis

SANY STS Crane Specifications

The collapsed crane represented cutting-edge port technology. SANY STS crane collapse Singapore port analysis reveals the following technical specifications:

Lifting Capacity: 65 tons maximum operational load Front Reach: 73 meters across vessel beam Back Reach: 22 meters landside operations Lifting Height: 55 meters above rail level Rail Gauge: 35 meters between running rails Special Features: Intelligent 3D navigation system, double-trolley configuration

Double-Trolley Technology Impact

The ship-to-shore crane accident investigation focuses heavily on the double-trolley system. This advanced configuration allows simultaneous container handling operations, significantly improving throughput efficiency.

However, the double-trolley design introduces additional structural complexity. Port equipment failure analysis experts note that this configuration requires precise weight distribution calculations during installation phases.

Installation Procedure Analysis

Standard STS Crane Installation Protocol

Crane installation safety procedures typically involve multiple phases. The maritime infrastructure incident occurred during the critical positioning phase, when the crane structure transitions from transport configuration to operational setup.

Professional installation teams follow strict protocols including foundation verification, structural assembly sequences, and comprehensive load testing. The SANY STS crane collapse Singapore port analysis suggests potential deviation from standard procedures.

Risk Factors During Installation

Ship-to-shore crane accident investigation reveals several critical risk factors. Foundation stability represents the primary concern during heavy crane positioning operations.

Wind conditions, structural alignment precision, and temporary support systems all contribute to installation success. Port equipment failure analysis indicates that any single factor deviation can precipitate catastrophic outcomes.

Singapore’s Tuas Port Development Context

Mega-Project Significance

Tuas Port represents Singapore’s most ambitious maritime infrastructure development. The facility aims to become the world’s largest automated container terminal by 2040.

Current operational capacity includes 11 active berths, with expansion plans adding 7 additional berths through 2027. The SANY STS crane collapse Singapore port analysis occurs within this rapid development context.

Operational Continuity

Despite the maritime infrastructure incident, Tuas Port operations continued without disruption. Active berths maintained normal throughput levels, demonstrating robust operational segregation protocols.

The ship-to-shore crane accident investigation benefits from this operational continuity, allowing detailed forensic analysis without time pressure from port closure requirements.

Investigation Methodology and Findings of SANY STS Crane Collapse at Singapore

Joint Investigation Approach

MPA and PSA Singapore established a comprehensive investigation framework. The port equipment failure analysis incorporates multiple technical disciplines including structural engineering, materials science, and operational safety protocols.

External technical experts supplement internal investigation capabilities. Crane installation safety procedures undergo complete review to identify potential improvement opportunities.

Preliminary Findings Assessment

While official conclusions remain pending, industry experts suggest several potential contributing factors. The SANY STS crane collapse Singapore port analysis considers foundation preparation adequacy, structural assembly sequence compliance, and environmental condition impacts.

Maritime infrastructure incident investigations typically require 3-6 months for complete analysis. The ship-to-shore crane accident investigation follows established international protocols for heavy equipment failure assessment.

Industry Impact and Safety Implications

Rare Incident Classification

Port equipment failure analysis experts emphasize the exceptional nature of this incident. STS crane collapses during installation represent extremely rare occurrences in modern port development.

Historical data indicates that most crane accidents involve operational impacts with vessels or extreme weather events. The SANY STS crane collapse Singapore port analysis represents an unusual case study for the maritime industry.

Global Safety Protocol Review

Crane installation safety procedures worldwide undergo review following significant incidents. Port authorities globally examine their installation protocols against lessons learned from the maritime infrastructure incident.

Equipment manufacturers also reassess delivery and installation guidance documentation. The ship-to-shore crane accident investigation findings will influence future industry standards development.

Technical Failure Analysis Theories

Structural Stability Considerations

The SANY STS crane collapse Singapore port analysis explores multiple structural failure scenarios. Foundation settlement, inadequate temporary bracing, and assembly sequence deviations represent primary investigation areas.

Double-trolley configurations require precise center-of-gravity calculations throughout installation phases. Port equipment failure analysis suggests potential miscalculation in weight distribution during positioning operations.

Environmental Factor Assessment

Singapore’s tropical climate presents unique challenges for crane installation safety procedures. High humidity, temperature variations, and wind conditions all influence structural stability during installation phases.

The maritime infrastructure incident occurred during typical afternoon conditions, eliminating extreme weather as a primary contributing factor. Ship-to-shore crane accident investigation focuses on procedural and technical aspects rather than environmental causes.

Economic and Operational Consequences

Direct Financial Impact

The SANY STS crane collapse Singapore port analysis includes substantial economic implications. Modern STS cranes represent multi-million-dollar investments, with replacement costs exceeding initial procurement expenses.

Insurance coverage typically addresses equipment replacement costs, but project delays introduce additional financial considerations. Port equipment failure analysis includes comprehensive cost assessment for stakeholder evaluation.

Schedule Impact Assessment

Tuas Port development timeline faces potential delays from the maritime infrastructure incident. Crane installation safety procedures require comprehensive review before additional equipment deployment.

The ship-to-shore crane accident investigation timeline directly impacts project completion schedules. Alternative equipment procurement may necessitate extended lead times for replacement crane delivery.

Manufacturer Response and Industry Reaction

SANY Heavy Industry Statement

SANY Heavy Industry cooperates fully with investigation authorities. The manufacturer’s technical team provides comprehensive documentation supporting the port equipment failure analysis process.

Quality control procedures and manufacturing specifications undergo detailed review. The SANY STS crane collapse Singapore port analysis benefits from manufacturer transparency and technical cooperation.

Industry Expert Commentary

Maritime engineering experts emphasize the learning opportunity presented by this maritime infrastructure incident. Crane installation safety procedures evolution depends on comprehensive incident analysis and industry knowledge sharing.

Professional associations coordinate technical information distribution ensuring global port development benefits from investigation findings. Ship-to-shore crane accident investigation results contribute to enhanced industry safety standards.

Future Prevention Strategies

Enhanced Installation Protocols

The SANY STS crane collapse Singapore port analysis drives development of improved installation procedures. Enhanced foundation verification, expanded structural monitoring, and redundant safety systems represent key improvement areas.

Port equipment failure analysis recommendations will influence future crane installation safety procedures globally. Maritime infrastructure incident prevention strategies incorporate lessons learned from this comprehensive investigation.

Technology Integration Opportunities

Advanced monitoring systems offer enhanced installation safety capabilities. Real-time structural stress monitoring, automated stability calculations, and predictive failure analysis represent emerging technologies applicable to ship-to-shore crane accident investigation prevention.

The maritime infrastructure incident highlights opportunities for technology integration improving overall installation safety performance. Future crane installation safety procedures will likely incorporate these advanced monitoring capabilities.

Conclusion

The SANY STS crane collapse Singapore port analysis provides valuable insights into modern port equipment installation challenges. While the ship-to-shore crane accident investigation continues, preliminary findings emphasize the complexity of heavy equipment deployment in maritime environments.

Port equipment failure analysis results will influence global crane installation safety procedures development. The maritime infrastructure incident serves as a critical learning opportunity for the international port development community.

Singapore’s response demonstrates exemplary crisis management and transparent investigation procedures. The comprehensive ship-to-shore crane accident investigation approach ensures thorough analysis supporting future prevention strategies.

Professional Maritime Services

When maritime infrastructure incidents occur, specialized expertise becomes essential for comprehensive analysis and resolution. Qualitas Marine Surveyors provides expert maritime consulting services tailored to complex port equipment challenges.

Our experienced team offers immediate response capabilities for damage surveys, conducting thorough assessments of vessel hulls, machinery, and port infrastructure. We deliver complete, accurate reports quickly, ensuring stakeholders receive critical information for informed decision-making.

For legal proceedings involving maritime incidents, Qualitas Marine Surveyors provides expert witness testimony across multiple disciplines including vessel operations, cargo handling, navigation systems, and equipment failure analysis. Our professional testimony supports litigation requirements with authoritative technical expertise.

Maritime casualty investigations represent our core specialty, delivering cost-efficient services for accurate cause determination and mitigating factor assessment. Our engineering expertise combined with extensive marine experience ensures impartial, comprehensive incident analysis.

Contact Qualitas Marine Surveyors today to discuss your maritime consulting requirements. Our crisis management capabilities and risk mitigation expertise provide the professional support your organization needs during challenging maritime situations.

References: